OUR WORK

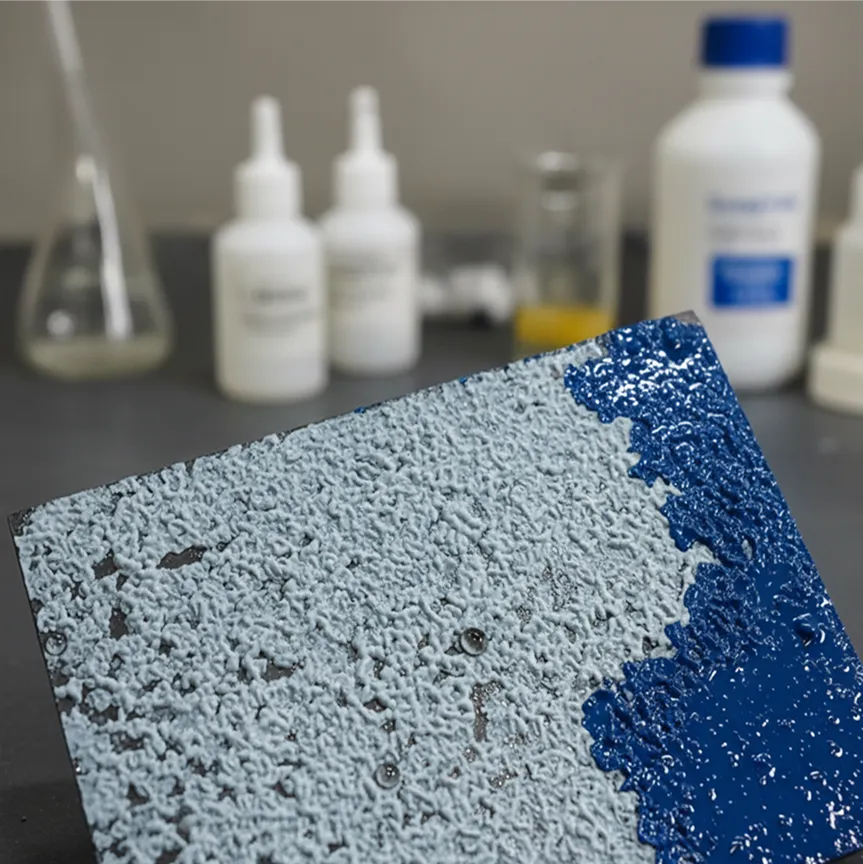

MOLY COATING

Molybdenum disulfide (Moly) is a solid additive, most commonly used in extreme pressure applications. It is used post Zinc phosphating as a dry lubricating layer as it has one of the lowest coefficient of friction and a very high operating temperature

ZINC PLATING

The fundamental aim of zinc electroplating is to protect metals from rust or corrosion. Zinc plated coatings are also known as sacrificial coatings because the zinc coating sacrifices itself to protect the underlying metal from corrosion. Zinc electroplating has to do with the electro-deposition of a thin layer of zinc metal on the surface of another metal which is known as substrate. The zinc coating serves as physical protection which prevents rust from affecting the underlying metal surface.

MANGANESE PHOSPHATING

Manganese phosphating is extensively employed to improve the sliding properties of engine, gear, and power transmission systems. Manganese phosphate coating has the highest hardness and superior corrosion and wear resistances of general phosphate coatings. The use of manganese phosphated coatings for improved corrosion resistance can be found in virtually all branches of the metal working-industry. Typical examples mentioned here include motor vehicle components in brake and clutch assemblies, engine components, leaf or coil springs, drill bits, screws, nuts and bolts, washers, anti-vibration washers, tools, magnet cores, casting interiors and many other small items.

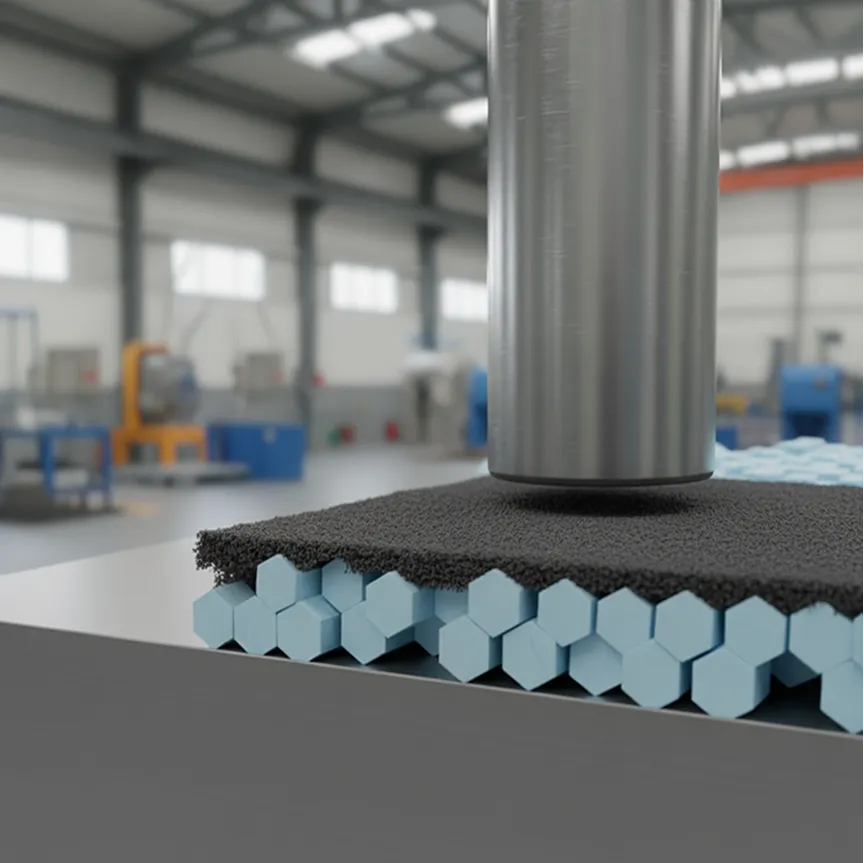

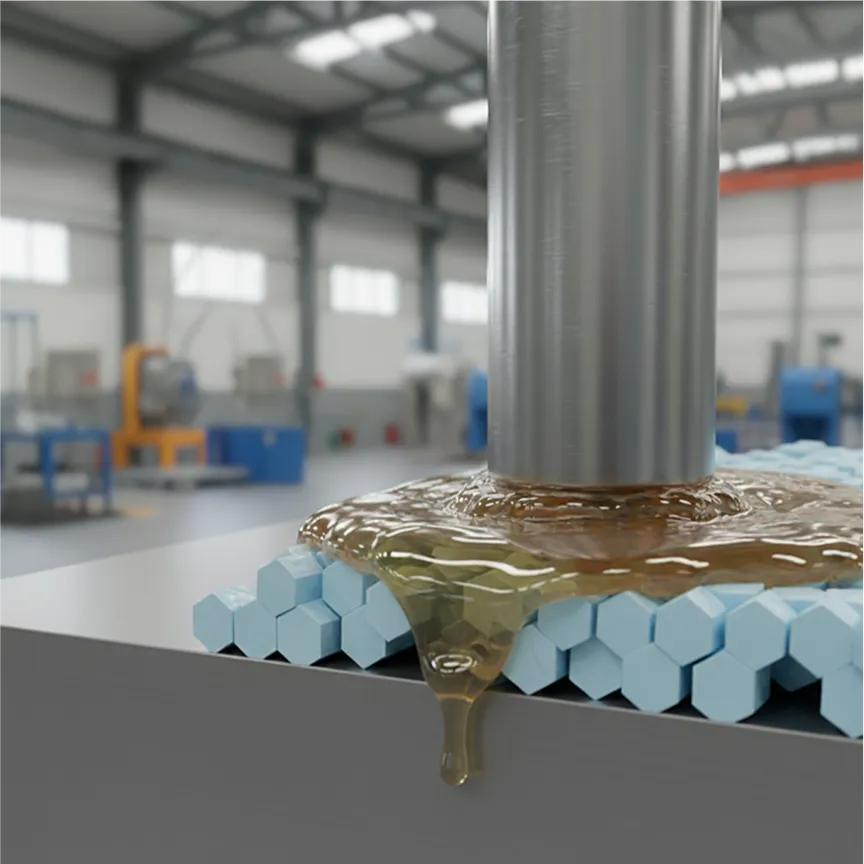

ZINC PHOSPHATING

Zinc Phosphating is a conversion coating wherein the metal surface mostly iron and steel are converted into their corresponding metal phosphates by chemical reactions. Zinc phosphate coatings are used for corrosion resistance, as a lubricant-holding layer, and as a paint/coating base. It is widely used in the wire drawing works, automotive industry and in certain sectors of the appliance and electronics industries.Zinc phosphate coatings play a key role in holding lubrication for the component to be forged / cold worked subsequently.

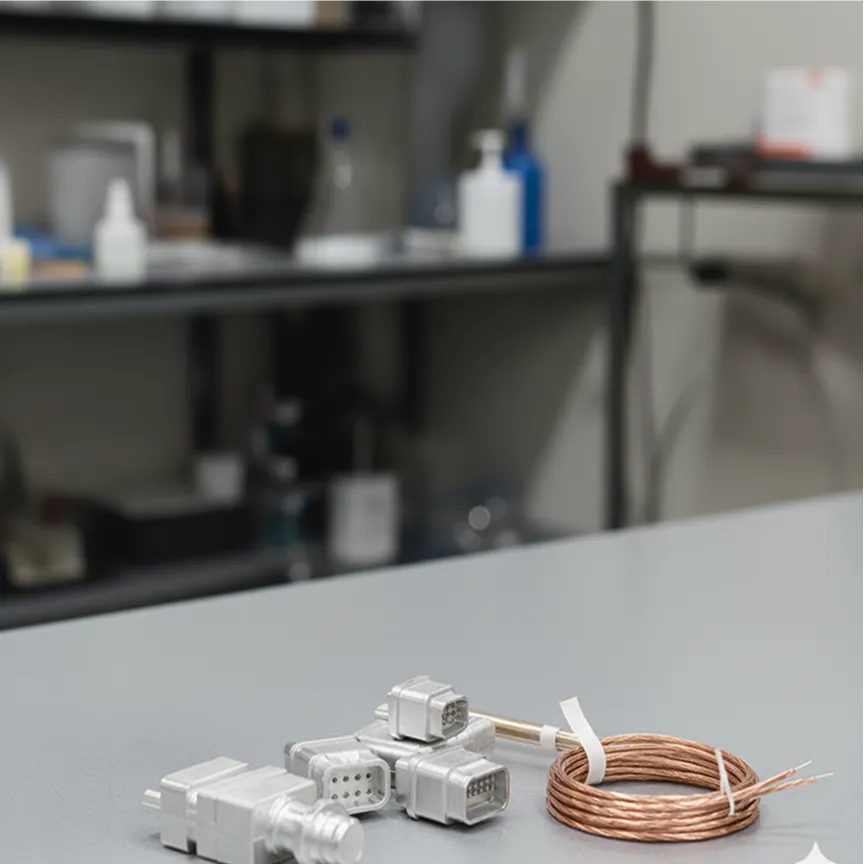

TIN PLATING

Tin is a soft, ductile, silvery-white metal that is not easily oxidized in air. It has good conductivity and corrosion resistance while enhancing solderability of substrates that are not otherwise easily soldered to. For substrates alloyed with zinc (such as brass alloys) it is generally recommended to apply a diffusion barrier of nickel plating or copper plating to prevent zinc migration into the tin deposit and resultant intermetallic formation.

NICKEL PLATING

In addition to creating an aesthetically-pleasing product, nickel is also sought after for its corrosion-resistant properties. It also improves solderability and lubricity. Nickel provides a great combination of corrosion and wear resistance. It can provide excellent adhesion properties for subsequent coating layers, which is why it is often used as an “undercoat” for other coatings. It is widely used commercially because of its beneficial properties and versatility as a coating material. The properties and appearance can be customized to specific needs.

SILVER PLATING

Silver finishes are usually recognized as a decorative coating, but is also an engineering coating due to its superior conductivity and corrosion resistance. Silver’s conductivity allows for extensive use in electrical components. Silver is the least expensive precious metal, so a silver plating solution is far less costly than choosing gold, platinum or palladium and should be the first option if considering using a precious metal.

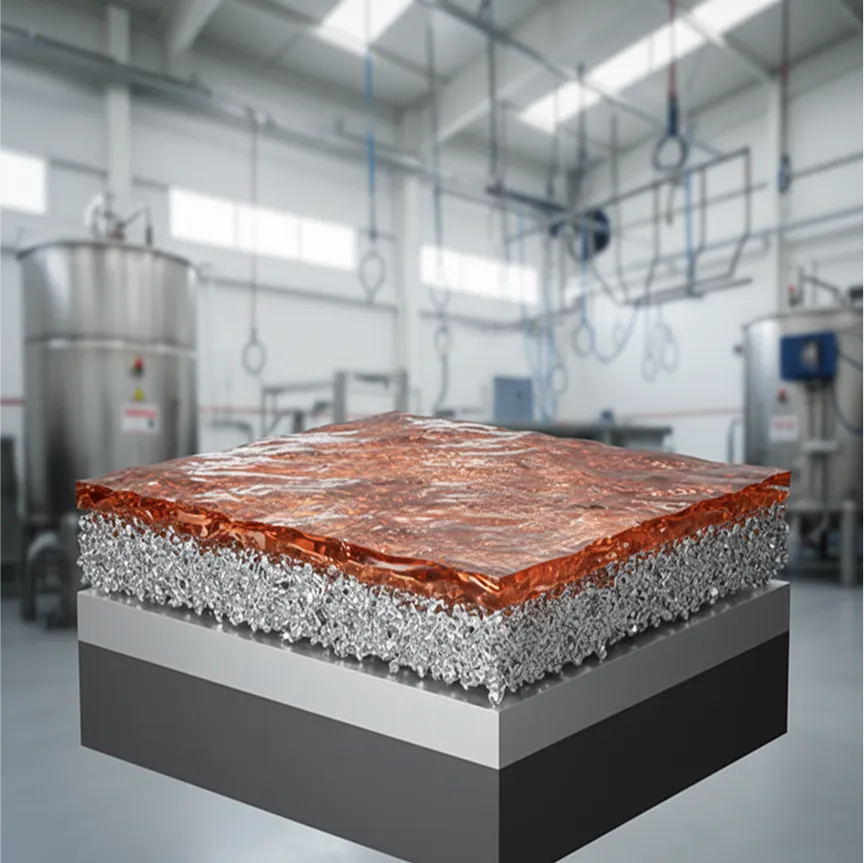

LUBE COATING

Lube coating is used post zinc phosphating to provide lubrication to the metal surfaces prior to cold forging. The lube reacts with the phosphate crystal to bond to the metal surface.